MEASURING INSTRUMENTS

Micrometers Micrometers |

|

Vernier Calipers Vernier Calipers |

Depth Gauges Depth Gauges |

Dial Calipers Dial Calipers |

Height Gauges Height Gauges |

Special Calipers Special Calipers |

|

Digital Indicators Digital Indicators |

|

Others Others |

Article

A caliper (British spelling also calliper) is a device used to measure the distance between two symmetrically opposing sides. A caliper can be as simple as a compass with inward or outward-facing points. The tips of the caliper are adjusted to fit across the points to be measured, the caliper is then removed and the distance read by measuring between the tips with a measuring tool, such as a ruler.

They are used in many fields such as metalworking, mechanical engineering, gunsmithing, handloading, woodworking, woodturning and in medicine.

Contents |

Nomenclature variants (colloquial only)

A plurale tantum sense of the word "calipers" coexists in natural usage with the regular noun sense of "caliper". That is, sometimes a caliper is treated cognitively like a pair of glasses or a pair of scissors, resulting in a phrase such as "hand me those calipers" or "those calipers are mine" in reference to one unit. However, this usage is mostly colloquial and the regular noun sense of caliper usually dominates, especially in writing. There is no rigorous grammatical logic to defend the plurale tantum sense; it is just the way language sometimes naturally flows colloquially.

Also existing colloquially but not in formal usage is referring to a vernier caliper as a "vernier".

Types

Vernier caliper

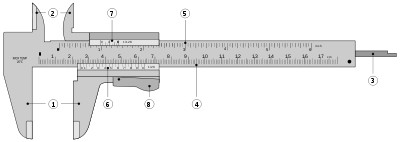

- Outside jaws: used to measure external diameter or width of an object

- Inside jaws: used to measure internal diameter of an object

- Depth probe: used to measure depths of an object or a hole

- Main scale: gives measurements of up to one decimal place(in cm).

- Main scale: gives measurements in fraction(in inch)

- Vernier gives measurements up to two decimal places(in cm)

- Vernier gives measurements in fraction(in inch)

- Retainer: used to block movable part to allow the easy transferring a measurement

A variation to the more traditional caliper is the inclusion of a vernier scale; this makes it possible to directly obtain a more precise measurement.

Vernier calipers can measure internal dimensions (using the uppermost jaws in the picture at right), external dimensions using the pictured lower jaws, and depending on the manufacturer, depth measurements by the use of a probe that is attached to the movable head and slides along the centre of the body. This probe is slender and can get into deep grooves that may prove difficult for other measuring tools.

The vernier scales may include both metric and inch measurements on the upper and lower part of the scale.

Vernier calipers commonly used in industry provide a precision to a hundredth of a millimetre (10 micrometres), or one thousandth of an inch.

A more precise instrument used for the same purpose is the micrometer.

Dial caliper

A further refinement to the vernier caliper is the dial caliper.In this instrument, a small gear rack drives a pointer on a circular dial. Typically, the pointer rotates once every inch, tenth of an inch, or 1 millimeter, allowing for a direct reading without the need to read a vernier scale (although one still needs to add the basic inches or tens of millimeters value read from the slide of the caliper). The dial is usually arranged to be rotatable beneath the pointer, allowing for "differential" measurements (the measuring of the difference in size between two objects, or the setting of the dial using a master object and subsequently being able to read directly the plus-or-minus variance in size of subsequent objects relative to the master object.

The slide of a dial caliper can usually be locked at a setting using a small lever or screw; this allows simple go/no-go checks of part sizes.

Digital caliper

A refinement now popular is the replacement of the analog dial with an electronic digital display on which the reading is displayed. Some digital calipers can be switched between metric and inch units. All provide for zeroing the display at any point along the slide, allowing the same sort of differential measurements as with the dial caliper but without the need to read numbers that may be upside down. Digital calipers may contain some sort of "reading hold" feature, allowing the reading of dimensions even in awkward locations where the display cannot be seen.With all of these benefits, digital calipers have by no means replaced the dial caliper. Digital calipers typically do not have the beam structure of a dial or vernier caliper and therefore do not have the repeatability or accuracy to an amateur user.

Ordinary 6-in/150-mm digital calipers are made of stainless steel, have a rated accuracy of .001" (.02mm) and resolution of .0005" (.01mm). The same technology is used to make longer 8-in and 12-in calipers; the accuracy for bigger measurements declines to .001" (.03mm) for 100-200mm and .0015" (.04mm) for 200-300mm.

Increasingly, digital calipers offer a serial data output to allow them to be interfaced with a personal computer. This means measurements can be taken and instantly stored in a spreadsheet or similar piece of software, significantly decreasing the time taken to take and record a series of measurements. The output of non-name brand calipers is usually 24 bit 90 kHz synchronous. A suitable interface to convert the output to RS-232 levels and format can be built or purchased.

Like dial calipers, the slide of a digital caliper can usually be locked using a lever or thumb-screw.

Digital calipers contain a linear encoder. A pattern of bars is etched directly on the Printed circuit board in the slider. Under the scale of the caliper another printed circuit board also contains an etched pattern of lines. The combination of these printed circuit boards forms two variable Capacitors. As the slider moves the capacitance changes in a linear fashion and in a repeating pattern. The two capacitances are out of phase. The circuitry built into the slider counts the bars as the slider moves and does a linear interpolation based on the magnitudes of the capacitors to find the precise position of the slider.

Vernier, dial and digital calipers can be used with accessories that extend their usefulness. Examples are a base that extends their usefulness as a depth gauge and a jaw attachment that allows measuring the center distance between holes.

Each of the above types of calipers have their relative merits and faults.

Vernier calipers are rugged and have long lasting accuracy,are coolant proof, resist magnetic fields and shock proof. Can have both metric and imperial scales. However they require good eyesight or a magnifiing glass to read and are hard to read from a distance or at awkward angles.

Dial calipers are easy to read especially when seeking exact center by rocking and observing the needle movement. They can be set to 0 at any point for comparisons. Cons, only moderately shockproof. Very prone to dirt in the gearing causing errors.

Digital calipers switch easily between metric and imperial systems. Can be set to 0 easily at any point with full count in either direction. Can take measurments even if the display is completely hidden by setting to 0 in place then withdrawing and closing completely which shows the measurement in negative. Cons, mechanically fragile, electronically fragile. Most require batteries. Most do not resist coolant well. Only moderate shock resistance. vulnerable to dirt.

The accuracy of all these types is basically the same at +/- .001" for 6" calipers.

Micrometer caliper

A caliper with a micrometer built in is called a micrometer caliper or, more often, simply a micrometer. (Sometimes the term caliper, referring to any other type in this article, is held in contradistinction to micrometer.A micrometer, sometimes known as a micrometer screw gauge, is a device used widely in mechanical engineering and machining for precision measurement, along with other metrological instruments such as dial calipers and vernier calipers. Micrometers are often, but not always, in the form of calipers. Colloquially the word micrometer is often shortened to mike.

Use

Accuracy of measurement when using a caliper is highly dependent on the skill of the operator. Regardless of type, a caliper's jaws must be forced into contact with the part being measured. As both part and caliper are always to some extent elastic, the amount of force used affects the indication. A consistent, firm touch is correct. Too much force results in an underindication as part and tool distort; too little force gives insufficient contact and an overindication. This is a greater problem with a caliper incorporating a wheel, which lends mechanical advantage. This is especially the case with digital calipers, calipers out of adjustment, or calipers with a poor quality beam.

Simple calipers are uncalibrated; the measurement taken must be compared against a scale. Whether the scale is part of the caliper or not, all analog calipers¡ªverniers and dials¡ªrequire good eyesight in order to achieve the highest precision. Digital calipers have the advantage in this area.

Calibrated calipers may be mishandled, leading to loss of zero. When a calipers' jaws are fully closed, it should of course indicate zero. If it does not, it must be recalibrated or repaired. It might seem that a vernier caliper cannot get out of calibration but a drop or knock can be enough. Digital calipers have zero set buttons.

Since the 1970s a clever modification of the moveable jaw on the back side of any caliper allows for "step"-measurements. For example: the distance from the side of a screw head to the edge of a surfac